The international Muon Ionization Cooling Experiment (MICE) on ISIS at RAL has established stable operation passing a muon beam through a 22l volume of liquid hydrogen. Operating with this volume of liquid hydrogen is a major technical challenge and is the culmination of several years work by personnel from Technology Department (RAL and DL), PPD and ISIS.

Muon beams are produced from the decay of pions captured from the debris that arises when a proton beam strikes a target. When produced in this way, an intense muon beam occupies a large volume in three-dimensional “physical space” and a large volume in six-dimensional “phase space”; such a beam is said to have a large emittance.

Muon beams of low emittance have been proposed as the basis of powerful facilities for the study of fundamental particles. To create such beams requires that the muon-beam emittance be reduced very quickly; in a time short compared to the lifetime of the muon (2.2 microseconds). At production, a bunch of muons from the beam occupies a volume comparable to that occupied by a water melon and is highly divergent. To accelerate and manipulate the beam requires that the size of the bunch transverse to its direction of motion be reduced such that, after cooling, the bunch occupies a volume comparable to that of a cucumber.

The MICE collaboration seeks to demonstrate that ionization cooling can deliver the required cooling effect. In an ionization-cooling channel the beam is passed through a material (the absorber) in which it loses energy and is subsequently accelerated. Liquid hydrogen is expected to give the best cooling performance. A systematic study of the factors that determine the ionization-cooling performance of a section of accelerator that contains an absorber composed of liquid hydrogen is therefore a critical step in the successful execution of the MICE experiment.

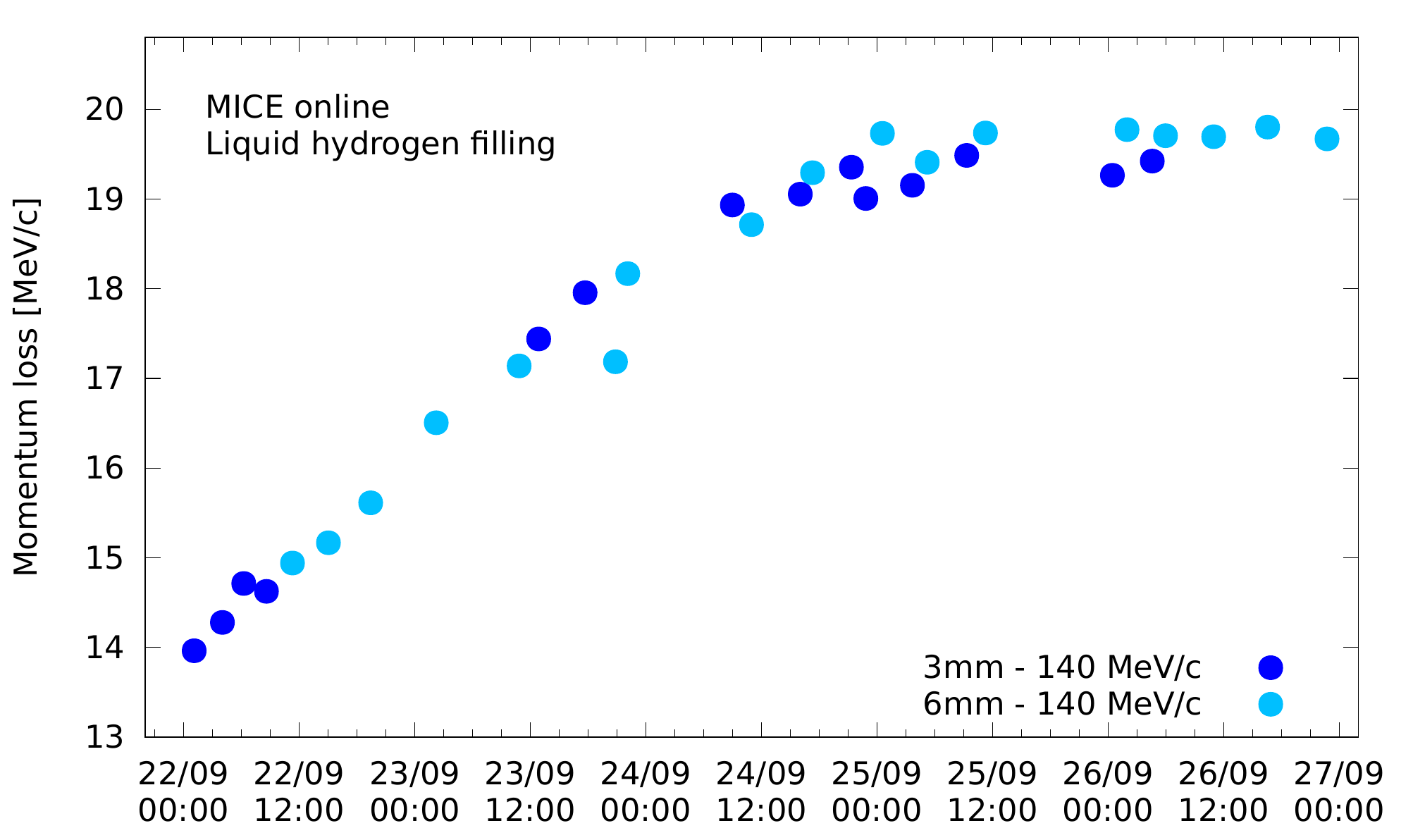

The MICE liquid-hydrogen absorber is filled by condensing hydrogen gas. The condensation rate is such that it takes roughly one week to fill the 22l volume of the absorber vessel. The vessel was filled for the first time late in the evening of the 25th September 2017. This success was the culmination of years work by personnel from Technology Division (RAL and DL), PPD and ISIS. The absorber vessel was designed and built at KEK in Japan. The detailed design of the 120micron thick aluminium windows was carried out by the Project Engineering Group at RAL and the University of Oxford. The windows were fabricated in the USA.

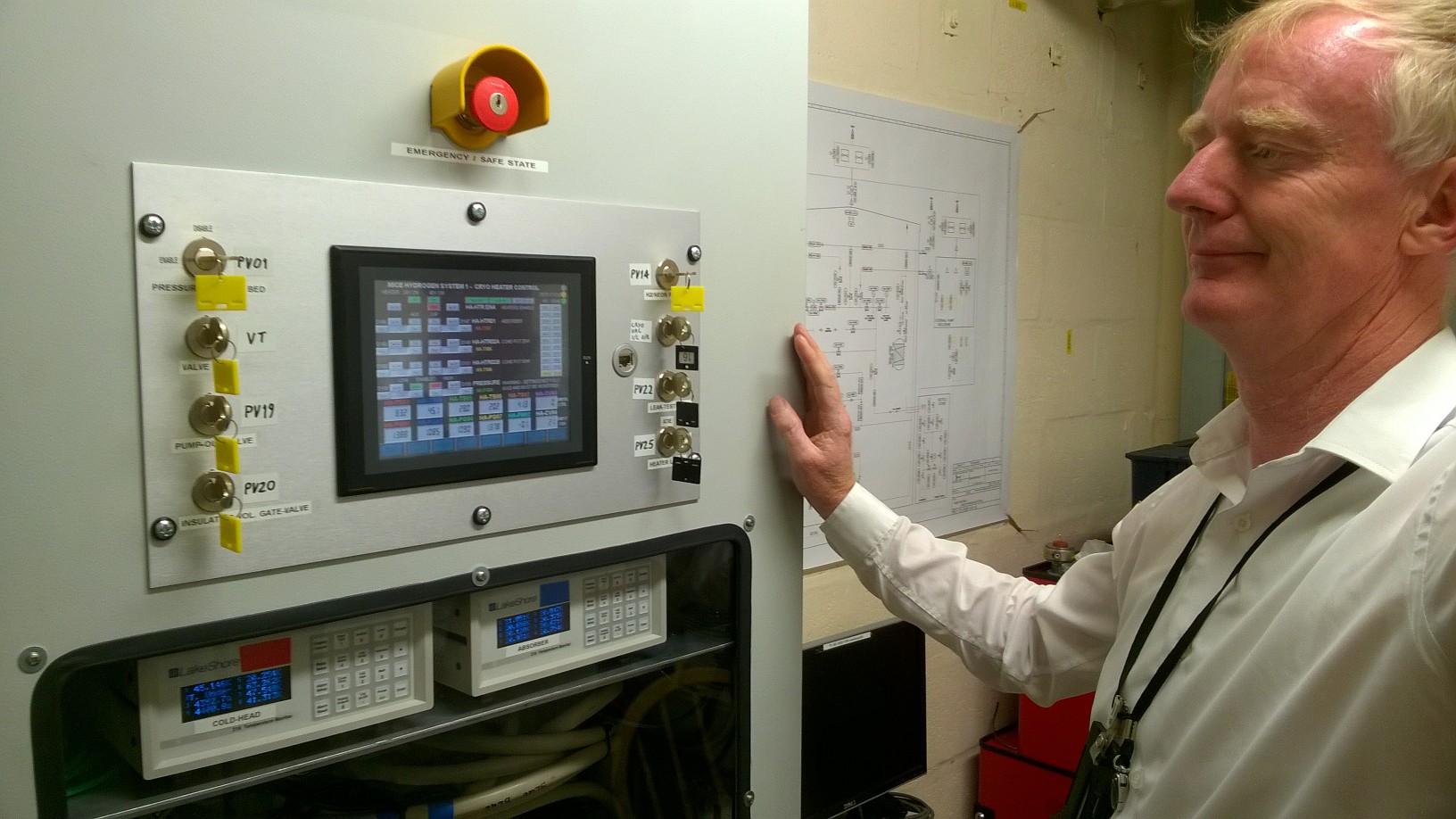

To make the system work required a full system-engineering approach that was guided by M.Hills, A.Nichols, S.Watson, M.Courthold, T.Bradshaw and later by V.Bayliss and J.Boehm all of Technology Department at RAL and M.Tucker of PPD. The critical control system was delivered by P.Warburton from the Electrical Engineering Group in Technology Department at DL. The DL Control Systems and Safety Interlocks Group made critical contributions to the integrated safety-engineering approach that was adopted from the outset and delivered through a close collaboration between personnel from Technology and ISIS Departments. Personnel from the Particle Physics Department provided the “mission need” and M.Tucker, supported by S.Balashov, delivered the critical vacuum and gas-handling systems.

For the MICE collaboration establishing stable operation with liquid-hydrogen is a major milestone that allows the critical study of the factors that determine the ionization-cooling effect to be carried out. For STFC the successful completion of the liquid-hydrogen system demonstrates the strength of the cross-campus, inter-disciplinary collaboration necessary to deliver such a technically-demanding project.