Yikai Wang is a PhD student at Kings College London. His research focuses on understanding how nanomaterials interact with the body and finding better ways to make advanced medical treatments. To support his research, Yikai has been using the facilities at Royce at Imperial including the Electron Beam Lithography, PVDs, ICP-RIE and SEM.

In this blog post, he discusses her research and his experience using the Royce facilities at Imperial.

Can you tell us more about your PhD project?

Working in the Chiappini Lab at King’s and LCN, we make high aspect ratio nanostructures known as nanoneedles to direct cell behaviours. Our research focuses on two areas: understanding the fundamental interactions between nanomaterials and biological systems, and to improve the manufacturing processes for advanced therapies.

Why did you use Royce facilities for your work?

My PhD research on high aspect ratio nanostructures requires specialised and advanced nanofabrication tools. Royce is renowned for its comprehensive range of such equipment, making it a great fit for my project. As a PhD student, I have also benefited from the Royce access scheme, which offers invaluable opportunities for PhD students in London to use the facilities. Furthermore, I remember hearing about the White City campus during its construction while I was doing my master’s at Imperial, so it is truly exciting to now use Royce’s fully operational facilities for my PhD studies!

Which facilities did you use at the Royce facility?

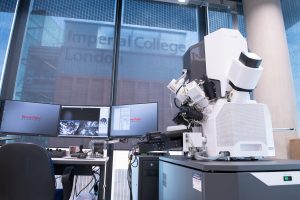

I use a wide range of facilities at Royce, including electron beam lithography, PVDs (thermal evaporation deposition, electron-beam deposition, magnetron sputtering), ICP-RIE and scanning electron microscopy (SEM).

How did using the Royce facility support your research?

Since my home institute primarily focuses on biology, the advanced nanofabrication tools at Royce, like EBL and ICP-RIE, were essential for my interdisciplinary research. They allowed me to create high aspect ratio nanostructures, enabling the precise manipulation of cell membranes and studying bio-nano interactions. This access directly facilitated the development of functional materials for cellular applications, significantly advancing my research.

Did you have any new learning experiences during your time at the Royce facility?

My foundational knowledge of nanofabrication was developed during my MSc at Imperial (actually Dr Peter Petrov gave our MSc lectures). However, it is at the Royce facility where I have truly honed those skills through hands-on experience with the advanced equipment. This practical training has been essential for my PhD research, especially as I have moved to cell biology, letting me apply nanofabrication to study cells in novel ways. This shift has shown me the value of interdisciplinary research, connecting nanotechnology with biology. Beyond the technical skills, I have also gained valuable insights into translational research through scale-up spaces at White City and Royce’s seminars, deepening my understanding of how scientific innovation can have a broader impact.

Royce at Imperial is a hub for start-ups, industry and academia to make, test and characterise materials, components and systems. If you are interested in using the facilities, please visit the Royce at Imperial website to learn more about the facilities and get in touch with our team.

We also send a bi-monthly newsletter with news, events and spotlight features. Sign up for our newsletter.

Comprehensive Resources: Royce provides a full suite of devices, from basic wafer cleaning to advanced thin film deposition and etching. This array of equipment allows us to conduct all necessary research under one roof without the need to seek additional facilities.

Comprehensive Resources: Royce provides a full suite of devices, from basic wafer cleaning to advanced thin film deposition and etching. This array of equipment allows us to conduct all necessary research under one roof without the need to seek additional facilities. What facilities do you use/did you use at the Royce facility?

What facilities do you use/did you use at the Royce facility?

Can you tell us more about your role – what does a typical week involve?

Can you tell us more about your role – what does a typical week involve? Can you tell us more about the facilities at Royce?

Can you tell us more about the facilities at Royce?