We are pleased to announce that our Level 1 Teaching Lab has received a Bronze LEAF Award for sustainable laboratories.

If you’ve ever visited EEE’s Level 1 Lab you’ll know it’s a huge space in constant use. A dynamic and collaborative learning environment where up to 200 students can be working on hardware experiments to support their taught modules, alongside staff and teaching assistants.

This means that power supply units, oscilloscopes, soldering irons, and computers for analysis and simulation of electronic circuits are running throughout the day, consuming a significant amount of energy. To add to the sustainability challenge, many thousands of electronic components are used over a year.

The LEAF Laboratory Efficiency Assessment Framework scheme is designed to improve sustainability and efficiency in higher education teaching and research. Labs undergo self-assessment and peer review to reach Bronze, Silver or Gold standard, demonstrating the estimated financial and carbon savings their actions have achieved. Imperial estimates that 247 tonnes CO2 equivalent has been saved through the LEAF scheme across the university since the start of 2024.

Leading the challenge

Sustainability lead in the lab is Electronic Support Group Technician May Tang. May has already been active in sustainability efforts for more than two decades as a member of our Technical Services team, who have all helped towards this achievement, supported by fellow technicians Vic Boddy and Amine Halimi, Technical Services Manager Danny Harvey, Teaching Fellows Dr Ed Stott and Dr Hakan Merdan, and Ben Gray, Imperial’s Sustainability Initiatives Coordinator. May says the team is “deeply committed to environmental stewardship and promoting sustainable practices in the scientific community.”

“Embracing and integrating these practices aligns with Imperial’s broader commitment to reducing our ecological footprint. This is crucial for the longevity and ethical responsibility of scientific research.”

Practical action

To achieve the Bronze LEAF accreditation, the team has implemented a series of measures. “We’ve introduced sorting and recycling programmes for electronic components, adopted a more efficient procurement strategy to minimise waste, and optimised our energy use by reducing computer screen and oscilloscope brightness. We’ve also helped our students and staff adopt best practices, ensuring that everyone can contribute to our green goals.”

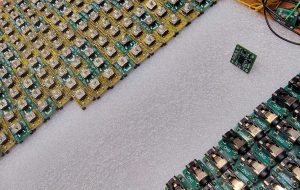

As well as taking simple steps such as using recyclable materials, and ensuring all equipment is well maintained to cut down on replacement, a notable innovation has been inspiring the students to design a recycling component sorting machine.

Future goals

Following this success, our department Stores will also now be applying for Bronze LEAF accreditation, and the Level 1 Lab team is aiming for Silver. May says: “This will involve further reducing our waste, enhancing our recycling programmes, and exploring new equipment and methods. We’d also like to collaborate with other labs to share best practice and drive collective progress toward greater sustainability.”

One of the changes they will be making in their bid for Silver is to upgrade the soldering irons. Technical Services Manager Danny Harvey explains: “On old soldering technology, the equipment stays on all the time, wasting energy. New smart soldering irons can supply just enough energy to meet the soldering task, and also turn off when not in action. This is not only safer and faster to operate, it also saves energy, and it reduces cost as the tips don’t burn out so quickly.”

Our congratulations to May and the team!