According to the UN, 2.4 billion people do not currently have access to basic clean water and sanitation, and each day, nearly 1,000 children die due to preventable water and sanitation-related diseases. Meanwhile, pollution from fertilizers, oil spills and human waste contaminate rivers, lakes and oceans. More than 80 percent of wastewater resulting from human activities is discharged into rivers or seas without any treatment to remove hazardous contaminants (Figure 1).

Given the UN Sustainable Development Goal 6 of delivering access to water and sanitation for all, how can new materials be deployed to help? Pavani Cherukupally is working on developing low-cost sponges which can remove pollutants from water.

Why use sponges to clean water?

Sponges are useful because their pores are big enough to absorb large pollutants, such as bacteria or oil droplets (micrometre scale), without clogging. The core concept is that they fill with polluted water, then the pollutant sticks to the sponge surface. The cleaned water is squeezed out, and then the pollutant can be washed off the sponge with a solvent and collected for reuse. The cleaned sponge can be used again to separate pollutants from wastewater.

This strategy is much cheaper and simpler than using the current standard water purification technologies. For wastewater, these include filtration, chlorination, UV treatment, ozonation or antibiotics. These are expensive, take time and (in the case of antibiotics) are becoming ineffective. For oil spills, clean-up typically uses technologies which exploit the difference in density between oil and water, such as floatation booms or inclined plate separators. However, these often require a pump, which makes them expensive to run, and they can also miss recovering the smallest oil droplets.

These challenges highlight why a combined molecular science and engineering approach is needed. It isn’t enough to deliver clever clean-up chemistry: the solution must also be easy to implement wherever it is needed, including in poorer countries or in remote regions, i.e., off grid. The ideal solution will be low cost, low energy, low emissions, scalable, non-toxic, reusable, easy to set up, commercially viable and culturally acceptable.

Changing the surface properties of a sponge

The cheapest sponges to use are made of plastic, for example polyurethane, which is used in cushions. These typically don’t have the ideal surface properties for cleaning contaminants out of water. So they need to be coated with another material which has surface chemistry that is complimentary to the pollutant. This way the bacteria or oil droplets will stick to them quickly like a magnet, while at the same time repelling water.

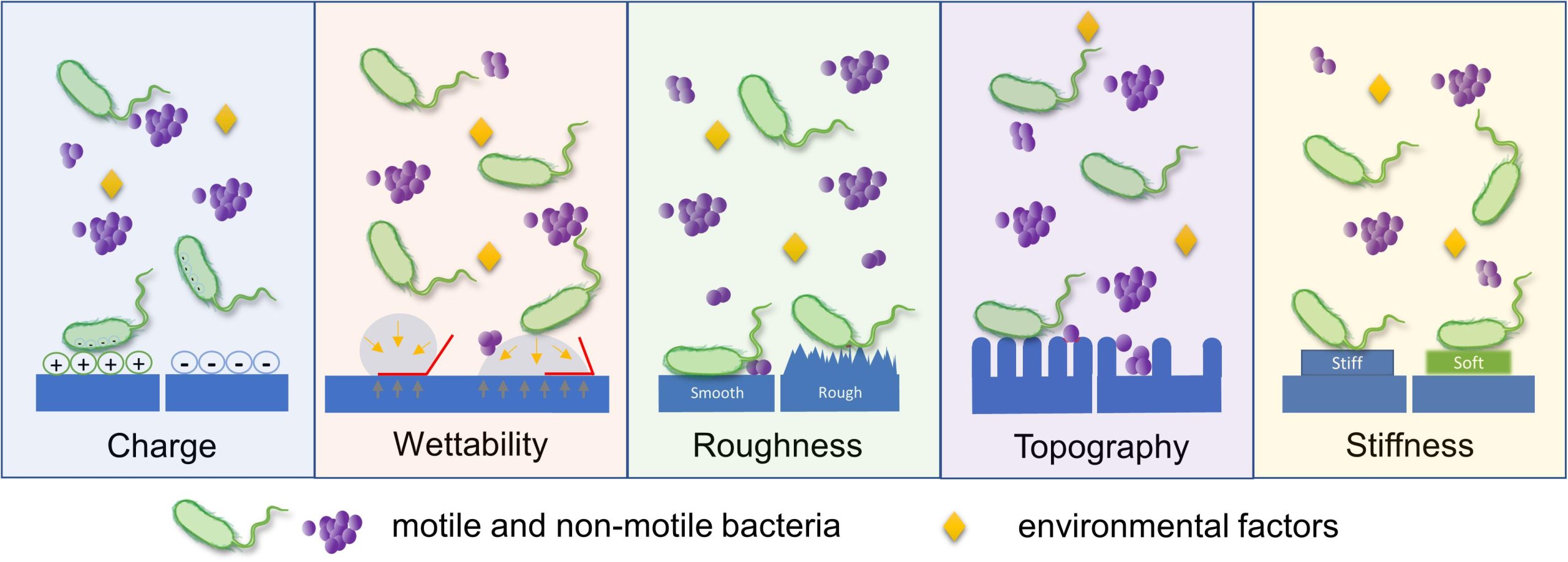

These coatings are carefully designed at a molecular level to interact with an oil droplet or a bacterium’s surface, to attract it and bind it. Some of the aspects of the coating that can be manipulated can be roughness, polarity (positive or negative charge) or the presence of specific chemical groups such as carboxy, amine or alkyl residues.

Cleaning bacteria out of wastewater

Pavani delivered a webinar for IMSE describing her work to develop a sponge which can remove bacteria from contaminated water. Here the sponge is a treatment process to generate grey water for reuse in low-income economies, like Rwanda, or off-grid communities, as in some parts of Scotland.

Bacteria attach to nutrient-rich surfaces using a range of chemical interactions, including electrical and shape-based forces (Figure 2). See IMSE’s briefing paper on designing surfaces with anti-microbial properties for more.

To clean the bacteria out of wastewater, a sponge was coated with a material with chemical groups (carboxy and amine) which change charge depending on the pH. The engineered sponge effectively removed bacteria from the water in 2.5 hours, but it was more effective if the water was acidic, than if it was neutral or basic.

After showing that the basic idea worked, the next step is to optimise the coating for real world conditions. This will make it effective against a range of bacteria, in a variety of environmental conditions, including a range of pH, temperature, salinity and fluid behaviour.

This work is a very practical contribution to addressing water challenges in low- and medium-income communities. But it also contributes to generating new basic scientific insights into material design and bacterial behaviour.

Recovering oil from the Arctic

Pavani was recently highly commended for the 2022 Sir William Wakeham award. This recognises outstanding early career researchers in the Department of Chemical Engineering at Imperial College London. Pavani was recognised for her work on using sponges with engineered surfaces to recover oil spills in the Arctic and other cold environments, and water disinfection technology.

There are currently over 1 trillion litres of contaminated water in oil sands tailings, sea and arctic oil spills. It’s especially difficult to recover oil from these environments because it partially crystallises at low temperatures, so the oil becomes waxy and flows more slowly. Pavani and her colleagues at Imperial College London and the University of Toronto designed a coating for a sponge (Figure 3) which is designed to mimic paraffin waxes, which are the elements in crude oil which go solid at low temperatures. This surface rejects water and absorbs oil, which sticks to the surface of the sponge.

Figure 3. Pavani Cherukupally in the lab with her prototype engineered sponge for cleaning contaminated water. The two bottles on the bench beside her show before and after treatment with the sponge.

The coated sponge absorbed 90-99% of tested oil within 3 hours, even at low temperatures (5°C), and could be easily cleaned with a solvent and reused with no loss of absorbency. The paper was published in Science Advances. This technology could be adapted to recover other viscous pollutants, such as paints.

Next steps for clean water

IMSE is delighted to be working with Dr Cherukupally to develop a briefing paper on affordable technologies for clean water. Read IMSE’s previous briefing papers.

Pavani was recently selected as a finalist for the 2022 Asian Women of Achievement Awards in the category Science.

She says: “We are on the verge of experiencing water scarcity with growing populations. On the other hand, the world also generates billions of litres of polluted water through industrial processes. We need affordable, sustainable technologies to close the wastewater cycle, that can also have other impacts like resource recovery from waste and reducing the water-borne disease burden around the world.”