Travelling by public transport, recycling our home waste, using re-fillable water bottles or taking a tote bag to the supermarket. We have all heard about the little changes we can do to reduce carbon emissions and protect the environment. However, the action with the biggest impact is related to food!

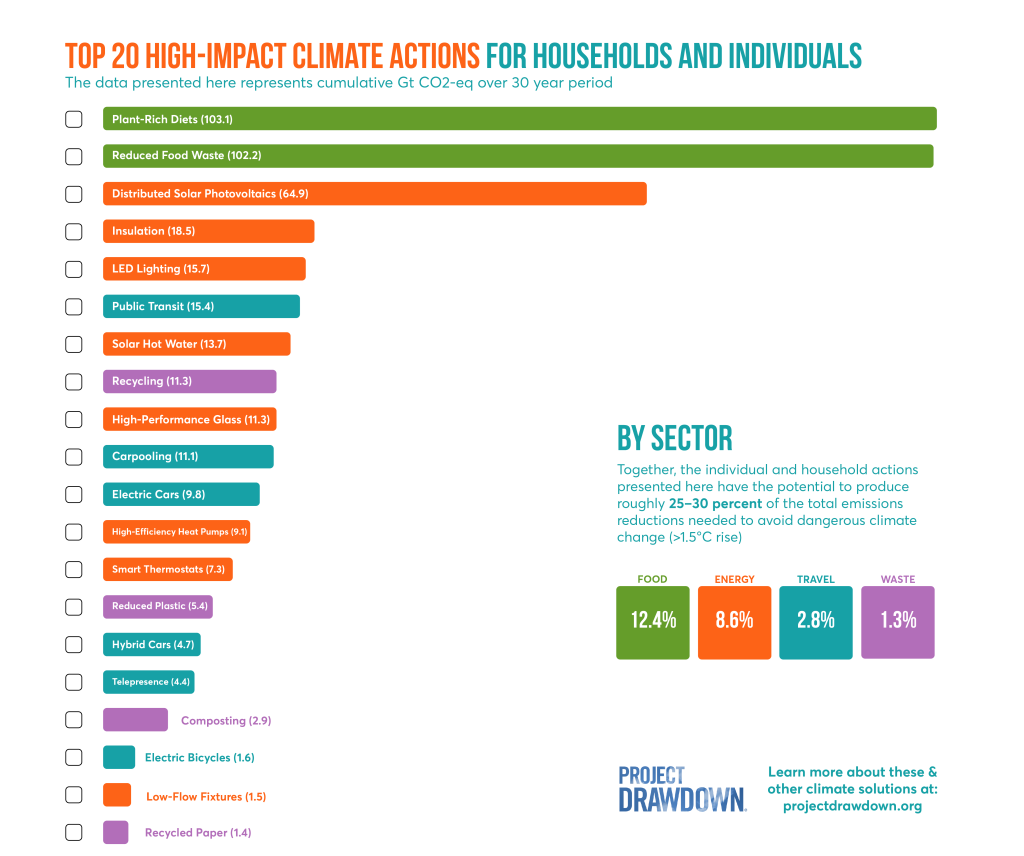

Project Drawdown has identified a series of practices and technologies with direct effect on emissions that are scientifically validated and economically viable.

A drop in the ocean?

Their analysis revealed that household activities could contribute to avoid dangerous climate change, defined as an increase in global temperature larger than 1.5°C. Individual actions have the potential to reduce the total emissions needed to avoid that temperature increase by 25-30%. Definitely not just a drop in the ocean! While large businesses and governments are responsible for most emissions (70-75%), our choices also play an important part.

How can we help?

Among the 20-high impact actions we find better home insulation, public transport and recycling. But above all, adopting a plant-rich diet and reducing food waste make up 12.4% of the 25-30% household potential for reductions. Adapting our diet and reducing the food we buy but don’t eat could really make a difference.