And I’m not talking about green food colouring, I’m talking about making formulations more sustainable.

In my last blog post, I gave some examples of formulations. These are complex mixtures of substances, in which each contributes to how the final product works. Medicines, personal care products, foods, lubricants, adhesives, paint and cleaning agents: these are all formulations. They’re everywhere in modern life.

So if we’re serious about decreasing our carbon footprint and increasing sustainability, then reducing the environmental impact of formulations will be valuable.

How can we work this out? There’s more than one contribution here:

- The energy and resources spent to develop the formulation in the first place.

- The energy and resources needed to manufacture the formulation.

- The energy and resources needed to use the formulation.

So reducing the climate impact of a formulation can target any of these three aspects.

Where’s the biggest impact?

Which contribution is greatest depends on the formulation. For Ariel washing powder, P&G calculated that 60% of the carbon emissions come from the energy used by the consumer to heat the water. 20% comes from ingredients, and the rest from manufacture, packaging and distribution.

In contrast, the same sort of analysis of a painkiller found that most of the emissions come from production of the product, not from using it (unsurprisingly).

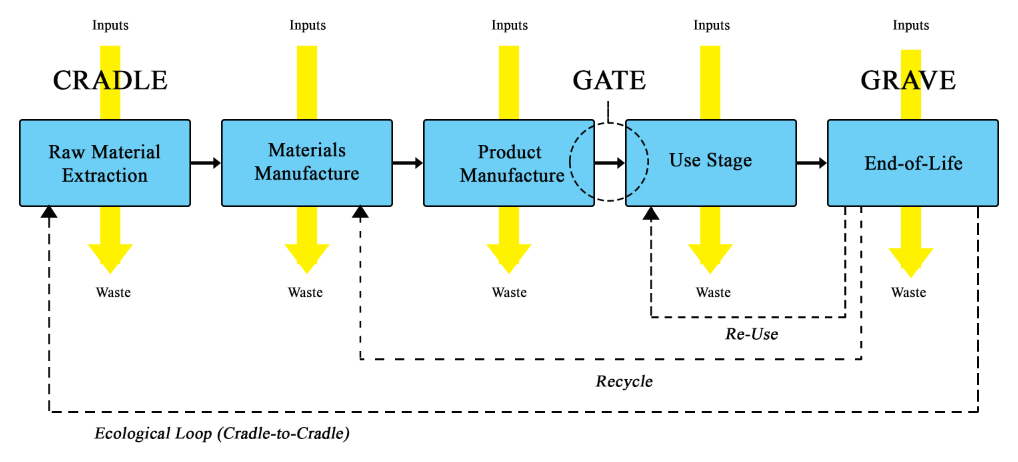

This kind of assessment is called a life cycle analysis. (IMSE’s recent briefing paper applied this assessment to low carbon aviation fuels). These calculations take into account all the resources used to make and use a product, including energy, water and materials. Effectively it’s a way of assessing the environmental cost of a product. It’s essential to developing more sustainable formulations.

Who needs to act to reduce this impact?

This depends on the formulation. If most of the impact is in using the product, then changing how consumers use it will make the biggest difference.

For a laundry detergent, washing your clothes at a lower temperature will reduce your carbon footprint from each individual load. But what if the detergent doesn’t work so well at lower temperatures, so you have to wash your clothes more often? Then there will be no overall reduction. So companies can contribute by developing a new formulation for a detergent that works well at a lower temperature.

They can also contribute by reducing emissions from the development, manufacture, packaging and distribution phases.

Companies vary hugely in their carbon intensity. One study found that the carbon emissions of the pharmaceutical industry are 55% higher than the automotive industry. And companies varied in how much carbon they emitted in their business by a factor of 5. Clearly there is scope for serious improvement here.

The scientists developing sustainable formulations

As companies become more focused on delivering sustainability targets, they need their employees to have new skills. In addition to be able to create new formulations, the next generation of formulations chemists will need to be able to work out ways to reduce the carbon footprint of their products. They’ll have to be able to use life cycle analysis to assess how to make sustainable formulations. This will include calculating the impact of:

- what they’re doing in the lab,

- what their suppliers are doing to produce raw materials,

- what their employers are doing in their manufacturing plants, and

- what their consumers are doing at home,

…and then changing the ingredients or the process in order to reduce the overall environmental impact of their product.

IMSE has been collaborating with the University of Leeds to develop a programme of training for Formulations at PhD level. In addition to the core science of formulations, this will include training in assessing the environmental impact of formulations. But it’s not just life cycle analysis. See the next blog for more…