Have you ever given an object a second life? Reusing yogurt pots to grow plants or a mug with a broken handle turned into a pencil holder. I recently made cushions out of coffee beans sacks from the nearby roasters. You probably also recycle glass bottles and carry a tote bag when going shopping, reducing the number of plastic bags.

From linear to circular economy

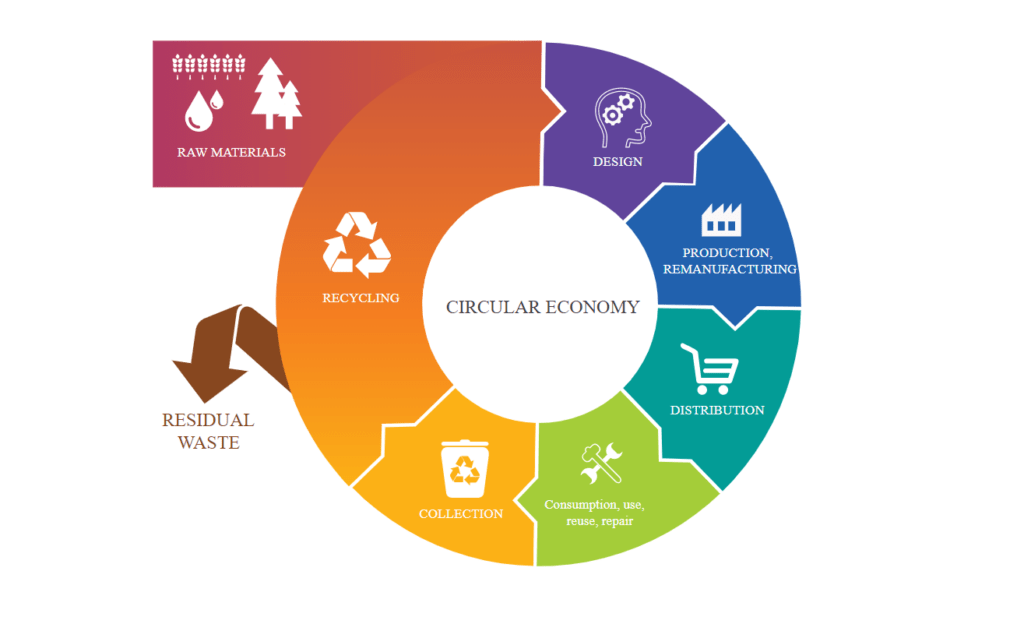

These are all examples of a circular economy. Established as a concept in the 70s, circular economy is the system of production and consumption that reduces waste to a minimum. Extending a product’s life is achievable by re-using, repairing, recycling and sharing, all of which create further value. Circular economy is the opposite of the linear economy model, where goods are simply thrown away after use.

Inventing new ways to reuse and recycle objects is fun and sustainable. However, it only tackles waste generation from the consumption side, ignoring the production and transport part of a product life cycle. Waste is not just created when an object is discarded but also beforehand, when it is made. Sourcing materials, fabrication processes leading to left-overs, transport and packaging also contribute to waste production.

What counts as waste?

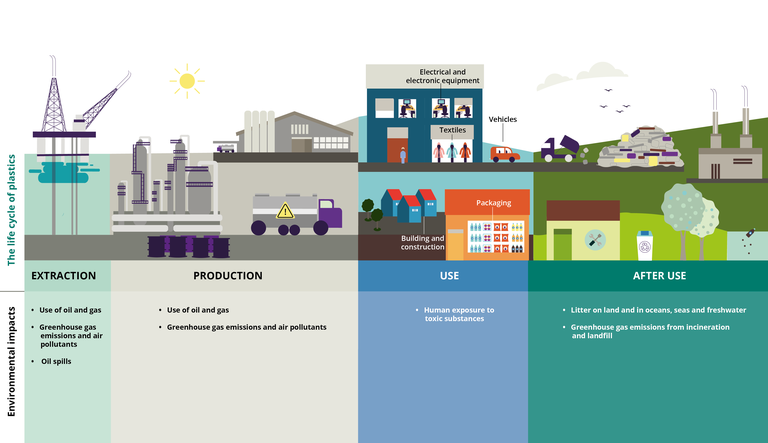

The first step towards achieving zero waste is to determine the stages at which it is produced. This can be done through an approach called life-cycle assessment (LCA). LCA is the evaluation of the environmental impact of goods or services throughout their entire life, from “cradle to grave”.

Multidisciplinary approach to achieve zero waste

Researchers at the Institute for Molecular Science and Engineering (IMSE) use the LCA approach to tackle waste at the beginning of the lifecycle, during the design phase. Using a molecular science approach, scientists examine materials’ structure and properties, considering how well they can be recycled. Meanwhile, from the engineering side, they assess manufacture processes and energy requirements, transport options and ultimately material performance.

Above all, the circular economy and LCA approaches aim to consider the entire life of a product. Improving one part of the cycle – e.g. manufacturing – should not simply shift the impact to another part of the cycle – e.g. recycling/degradation. Let’s think about plastics. Choosing an easier to recycle polymer to make a new plastic object could have consequences during transport and even function. Would faster degradation affect how we use an object or the way we transport it? The opposite also applies, making an object very durable will affect how it degrades and pollutes the environment after use.

Reaching zero waste will require a wide vision of the lifecycle, using multidisciplinary approaches and collaborating across expertise. That is not to say that you should stop reinventing objects you already have! The perfect occasion would be following the international day of zero waste on the 30th of March – what would you be re-using or repairing to celebrate?