Let’s check our shopping list, does it include items such as shampoo, detergent, margarine or cookies? According to the WWF, it is highly likely that some or all these items contain palm oil. You have probably heard about the negative connection between palm oil and deforestation and displacement of wildlife. However, you might be unaware of the large amount of waste generated during its production. Here, IMSE’s latest guest blogger, PhD researcher from Future Materials Group, Dharu Smaradhana, discusses his research into waste generated by palm oil production and its potential as sustainable material.

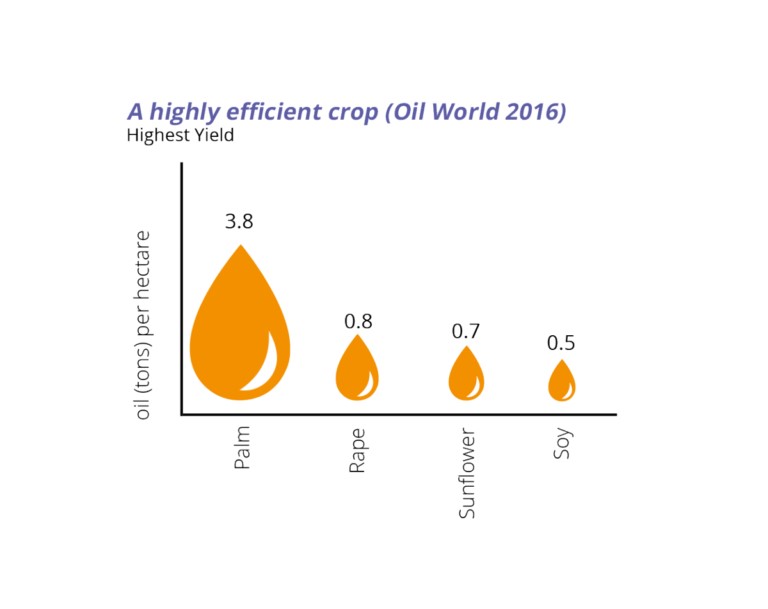

Palm oil is criticised due to deforestation concerns, but replacing it with other vegetable oils is not a straightforward solution. Palm oil is the most land-efficient vegetable oil crop. It supplies 40% of the world’s demand while using less than 6% of the land allocated for all vegetable oil production. Alternatives like soybean, coconut or sunflower oil require considerably more land which could lead to additional environmental damage.

Palm oil environmental impact beyond deforestation

Currently, nearly half of all packaged products contain palm oil, from foods and personal care items to animal feed and biofuels. Palm oil use is inevitable, but it carries environmental challenges. The Roundtable on Sustainable Palm Oil (RSPO) was founded in 2004 to promote sustainable palm oil production that protects forests and community rights. Nevertheless, mitigating the waste generated from palm oil production is another critical issue that needs addressing.

Production of palm oil generates many solid wastes, notably from empty fruit bunches (EFB). Every ton of palm oil generates around 1.1 tons of EFB. This bulky and moist waste presents considerable disposal challenges. Incinerating EFB contributes to environmental pollution, while simply discarding it results in the release of methane, thereby increasing greenhouse gas emissions.

Upcycling palm oil waste into construction materials

As material engineers, we also recognise the transformative potential of EFB in revolutionising the production of board products used in the construction and furniture industries such as particleboard and fibreboard. Conventionally, these boards are manufactured by combining wood fibres with synthetic binders like urea-formaldehyde, and then compressing the mixture under heat. However, these fossil-derived polymers present health hazards and pose environmental concerns due to their inability to degrade naturally.

Considering the challenges, EFB fibres emerge as an eco-friendly substitute for traditional wood fibres, enhancing sustainability in agriculture and industry. Our initiative involves producing EFB boards using cellulose from pulp as the binder, avoiding the use of synthetic products. Following simple manufacturing steps mimicking the paper-making process, EFB boards match the mechanical performance of commercial fibreboards.

Circular economy and climate change mitigation

Lifecycle assessment (LCA) studies also show that the EFB board substantially reduces the environmental impact. Particularly, in terms of global warming potential, when compared to traditional fibreboards that utilise fossil-derived binders.

By upcycling waste from palm oil production in such an innovative way, we are contributing to climate change mitigation and advancing towards a more sustainable, circular economy.