Last April, Arabella Heath, a Biochemistry undergraduate student, and Mia Hughes, a Chemistry undergraduate, joined IMSE for a day to experience the work environment in an Operations team. Together, they explored the topic of antimicrobial resistance and how we can keep antibiotics working by combining molecular science and engineering research. Coincidentally, a couple of weeks ago, the U.K. government updated its strategy to tackle antimicrobial resistance for the next 5 years. In this blog, Arabella and Mia explore how the surface of insect wings is inspiring innovation on antimicrobial ‘smart’ surfaces to reduce bacterial infections in hospitals.

The prevalence of antimicrobial resistance

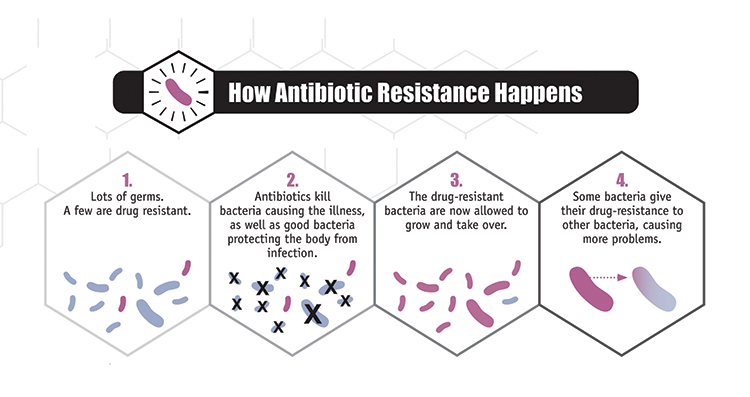

Summer is approaching, and we are all dreading the familiar sound of insects buzzing that accompanies the season. But who knew that studying some insects like cicadas and dragonflies might hold the key to tackling antimicrobial resistance (AMR)? AMR occurs when antimicrobial treatment is no longer effective at treating bacteria, viruses, fungi and other parasites. It leads to increased infections rates and severe illnesses. AMR is a major threat for the development of global public health. AMR caused an estimated 1.27 million deaths in 2019 worldwide and this is set to rise to 10 million by 2050. This issue requires new and innovative solutions because evolving bacteria are outsmarting our current available antibiotics.