Following on our blogs exploring circular economy and zero waste, we welcome our new guest blogger, Dr. Antonio Ovejero-Perez. A postdoc from the Department of Chemical Engineering, Antonio’s research is focused on extracting dyes from textiles waste.

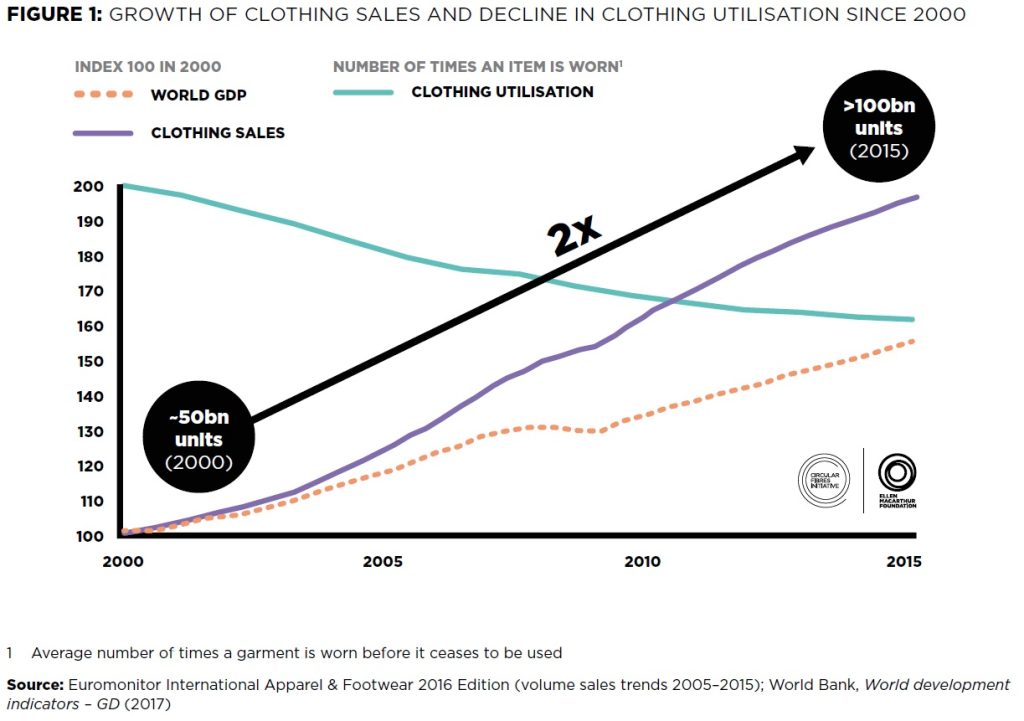

Who hasn’t heard a family member say: “Back in the day, I only got new clothing for Christmas or birthday”? Now, in our fast-paced world things have changed. How many times a year do we buy clothes? Trends come and go quickly, and “fast fashion” has become more and more popular.

But what is it? Fast fashion refers to the rapid production and consumption of inexpensive clothing items, often imitating current trends from the catwalk or celebrity culture. It prioritizes speed and affordability, resulting in frequent turnover of collections and low-cost garments. The New York Times first used the term to describe Zara’s mission to have garments in stores for just 15 days. This model involves design, production, and rapid distribution. Fast fashion creates large quantities of garments in very short periods of time at a low price.

This system encourages excessive consumption and clothes are used fewer times due to the social pressure of fashion trends. In addition, the consumer normally prefers to spend less money and change styles more often rather than buying more expensive garments that last long but will fall quickly out of popularity.

Fast fashion environmental consequences

The problem lies in the rapid production of garments. It is estimated that 92 million tonnes of textile waste are produced every year, expected to reach 34 million tonnes by 2030. The presence of dyes in the fabrics and the need for homogeneous input for fibre recycling complicates its recycling. Currently, textile waste is either incinerated or landfilled. Nowadays, recycled plastic bottles are the only source of recycled polyester for garment production, rather than recycled clothing. Thus, new raw materials are used for textile production: cotton (2.5% of farmland) and synthetic materials like polyester (342 million barrels of oil annually), driving environmental impact.

But textile waste accumulation is not the only problem of the fast fashion industry. The excessive demand of clothing requires huge amounts of energy that, normally, come from non-renewable sources. The textile and fashion industry accounts for a 10% of global carbon emissions, more than the aviation and shipping sectors combined. Water consumption is also substantial, accounting for 20% of global wastewater production per year. In addition, the textile dyeing part of the process uses 43 million tonnes of chemicals a year.

Tackling the fast fashion problem

But is it all the consumer’s fault? Consumers do have responsibility and the chance to change habits to put pressure on retailers. But the textile industry also needs to change, producing clothes more sustainably and reusing both dyes and textiles. As previously mentioned, textile recycling is limited by the presence of dyes; thus, technologies that are able to recover dyes from textiles are needed. However, making that in a sustainable way is not easy.

Recovering dyes from textile waste to be reused

In this sense, in our group, and in one of the startups founded in our group, DyeRecycle Ltd., we use a low-cost green solvent to selectively extract dyes from fabric wastes, enabling circular economy. Using this method, we can recover a decoloured polyester fabric with intact properties for mechanical and chemical recyclers. In addition, the dye-rich green solvent can be used as a dye bath to dye new garments, or be recovered and sold, as it comes unaltered out of the process. This way, our technology tackles textile accumulation and chemicals and water usage problems in one solution.