In our previous blog (Future of Food: Exploring the Rise of Cultivated Meat), guest bloggers, Wynsee Lu and Mekumi Chan, told us about the potential of cultivated meat as a sustainable food option. As they read articles on the topic, they discovered this industry goes beyond standard cell culture. In fact, there are a lot of additional aspects to consider for cultivated meat. Lab-grown meat is a great example of how we need to have molecular understanding to effectively engineer new products. In this blog, they explore the diversity in this industry and its potential for growth.

The molecular origin of flavour

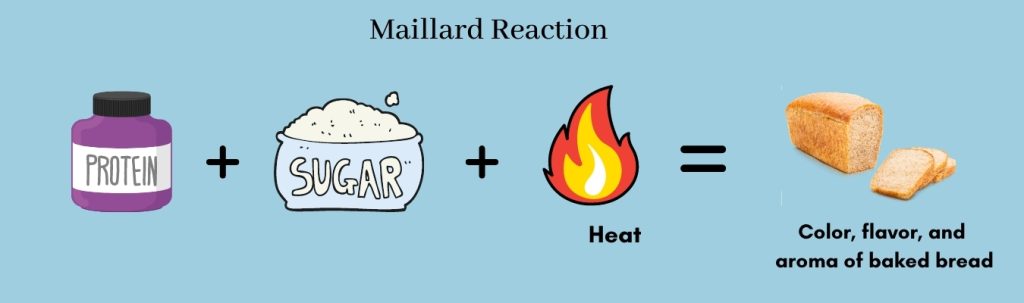

For consumers, the most important sensory characteristics of cultivated meats are the taste and texture compared to real meat. The main way industries have attempted to achieve the natural taste of meat within this sustainable food option is by mimicking the Maillard reaction. The Maillard reaction is the natural process that normal meats undergo when browning under heat to bring out aromas and flavours. Simultaneous chemical reactions between the amino acids and reducing sugars in the meat achieve the desired outcome. To mimic this, researchers use a temperature-sensitive flavour-switchable scaffold to enhance the aromatic properties of cultivated meats. This scaffold “switches on’ while cooking and the chemical reactions within it release crucial flavours to appease consumers. This is not the only way to reproduce the flavours of real meat and industries are developing new methods every day.

Scaffolds to build the right growth environment

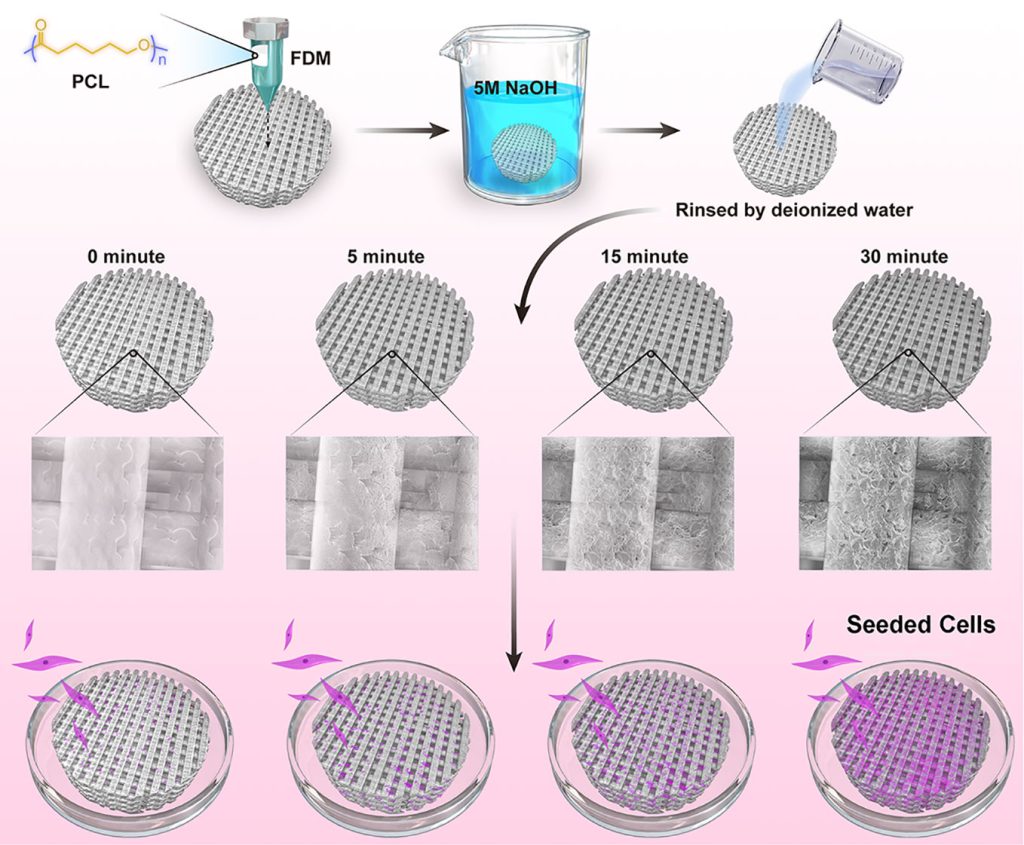

In the emerging world of technology, computational modeling is at the forefront of science. The use of 3D models has even extended to the industry of cultivated meats to select certain materials, shapes, or topography of scaffolds, allowing uniformity across a particular meat type. In addition, researchers are also investigating 3D microenvironments to grow and proliferate these stem cells instead of bioreactors. Cells are confined within 3D microenvironment, which can eradicate the shear stress presented by microcarriers and prevent the aggregate accumulation occurring in bioreactors. Through the science of scaffolding, scientists can ‘build’ the desired shape of cultivated meats.

Companies leading the way in the sector

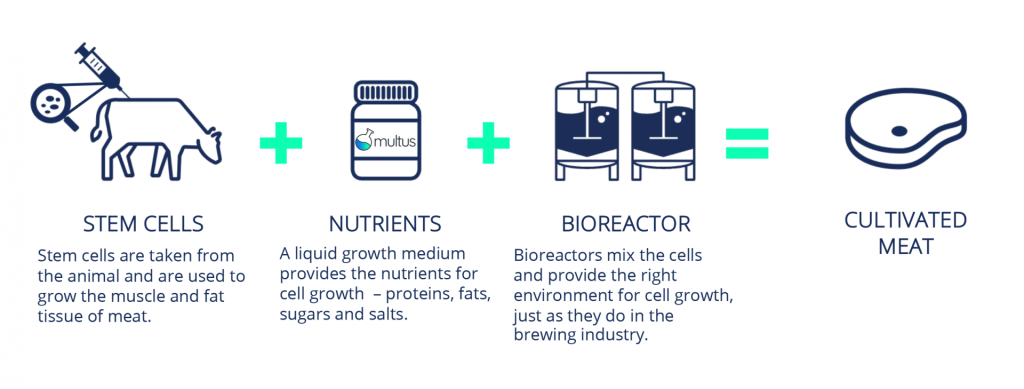

Some companies are already beginning to utilize this research to pave the way for the future of cultivated meats. London based, Hoxton Farms, are a company dedicated to improving the flavour of lab grown meats. By cultivating the precursor cells (stem cells) of pork fat in a blend of plant- based nutrients, these cells can successfully grow and mature into pork fat, a popular ingredient in dishes known for its strong umami flavour. This technology is scaled using modular cultivators showing that flavour does not need to be compromised when choosing sustainable meats.

Many vegans and vegetarians argue that while these sustainable meats do not involve the direct killing of animals, the growth of stem cells still require the use of animal products. Companies typically use foetal bovine serum (FBS) to cultivate the animal stem cells to grow their meats. However, FBS’s origin is the blood of a bovine foetus.

Therefore, there has been recent research into non-animal-based growth media that could be applied to the cultured meat industry. Multus, a start-up company based at Imperial College London has developed an alternative to FBS. Multus distributes up to 10,000 L of its serum each week to cultivated meat companies around the world. This development allows companies to manufacture animal- free meats.

Matrix Meats have also developed electro-spun nanofiber scaffolds that can be adapted to different meat development processes. Additionally, Aleph Farms are targeting the use of textured soy protein (TSP) as a material for this scaffold.

Potential for more improvements and companies in the sector

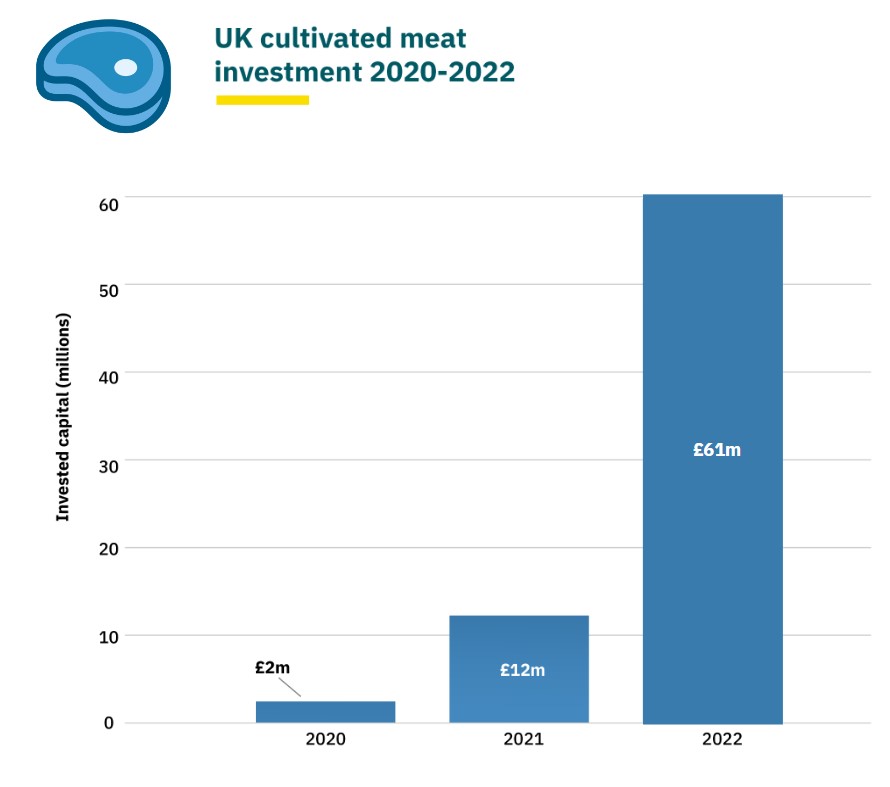

The future of cultivated meat does not stop at cell culture. Further research into the practicalities of developing large-scale production of cultivated meats has to be considered as an important part of the future food production. Moreover, the rise in industries highlights the potential to play a huge role for economic growth and resilience!