Our guest blogger, Mia Hughes is back to explore the topic of sustainable flavourings using chemical biology.

Grapefruit flavouring is in high demand around the world, for use in cakes, sweets, ice-cream and more. I myself consider a glass of grapefruit juice a refreshing treat. However, you may not know that grapefruit flavouring is actually one of the most expensive to produce in the world. This all comes down to the chemical compound Nootkatone, which gives grapefruit its flavour. A staggering 400,000 Kgs of Grapefruit are used to produce just 1 Kg of Nootkatone. This makes it hard to naturally source and in short supply. Researchers at Oxford Biotrans have responded to this issue by developing a new, sustainable way to produce Nootkatone – from oranges!

How can oranges create grapefruit flavouring?

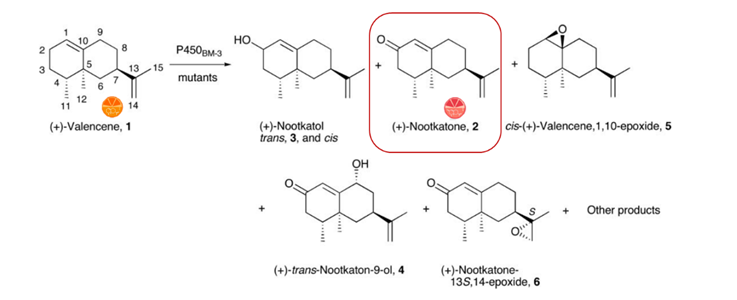

The answer lies with Valencene, a chemical with a very similar structure to Nootkatone. Valencene is an aroma compound which is naturally found in oranges, giving them their sweet, citrusy aroma. Unlike Nootkatone, Valencene is in abundant supply and can be extracted easily and inexpensively from oranges. Valencene can then be treated with a modified form of an enzyme, cytochrome P450, developed by Oxford Biotrans. This enzyme adds an Oxygen atom and removes 2 Hydrogen atoms from Valencene to produce Nootkatone.

Using an enzyme to produce Nootkatone is revolutionary with regards to sustainability. Although synthetic methods to produce Nootkatone exist, they consume a lot of energy and produce toxic by-products. These methods are therefore not environmentally friendly. The new process developed by Oxford Biotrans is much greener, as it is carried out with an enzyme. This means that the process can be carried out at room temperature and pressure and in a water medium, greatly reducing environmental impacts. In fact, WWF estimates that processes like these have the potential to save 2.5 Billion tons of Carbon Dioxide per year. This is the equivalent of taking 490 million cars off the road.

Industrial benefits

As well as being sustainable and cost-effective, this new process has commercial benefits for food industries. As Nootkatone is produced using an enzyme, it can be said to be made through a biological, not synthetic process. Nootkatone developed this way can therefore be labelled as a ‘natural’ flavouring, under EU regulations. This gives a great, sustainable solution for manufacturers – who have increasing pressure to use more ‘natural’ flavourings in their products.

Implementation

Researchers have shown that Nootkatone can be produced economically, sustainably and on an Industrial scale. However, the possibilities created by this process go beyond just fruit flavourings. In fact, Nootkatone has already been registered for use in insecticides and insect repellents under the US Environmental Protection Agency. Researchers are now looking to extend the process even further, to aid the production of pharmaceuticals and nutraceuticals. Who knows where a fruit-themed idea could take us next?