The RSM workshop, located on the lower ground floor of the Royal School of Mines, serves as a central machining facility providing design and manufacturing support for all three Departments within RSM: Materials, Bioengineering and ESE. It has a comprehensive range of both manual and CNC machines; some of the manual machines date back to the old Metallurgy workshop and have been in operation since the 1960s.

Russell Stracey, RSM Workshop Manager, became a part of the workshop team in 2008, while Mike Lennon, Mechanical Workshop Technician, joined in 2013. We had the opportunity to speak with Russell and Mike to learn more about the workshop’s evolution over time, exciting projects, and their personal highlights.

Can you tell us more about the workshop?

Mike: Workshops are important to produce of a wide range of goods. When you think about it, everything around you is likely created in a type of workshop, from transport to household items and clothing – it just depends on the size, scale, and capability of the facility. In the Department of Materials, we focus on making components that can support research or teaching – and we are always up for a new challenge!

Mike: Workshops are important to produce of a wide range of goods. When you think about it, everything around you is likely created in a type of workshop, from transport to household items and clothing – it just depends on the size, scale, and capability of the facility. In the Department of Materials, we focus on making components that can support research or teaching – and we are always up for a new challenge!

Russell: When you look around our workshop, there are a range of drilling, cutting and creating machines – both old and new. The workshop’s physical layout has undergone significant transformations throughout the years. When I arrived in 2008, it was three times its current size and occupied multiple floors! Furthermore, our team has expanded, welcoming additional staff members. Over time we have introduced CNC machines alongside traditional manual machines, enhancing our operational efficiency. Some of the old machinery still has a valuable purpose in supporting our work – the oldest facility here dates to the 1960s!

What’s a typical day like?

Russell: A typical day for us can be quite varied! We usually focus on machining experimental components for our PhD students and researchers to support their projects across a wide range of disciplines, from engineering alloys to medical and energy applications. We also manufacture samples for tensile testing that our UG students use during their labs

Most parts machined in the workshop are made from metal or plastic. In recent years, we have witnessed a growing demand for the use of new materials such as Peek. Peek is a fairly new material. It has become an increasingly popular material, replacing PTFE for sample holders, as it doesn’t contaminate the material which is being tested, is a more stable material from a machining perspective and is able to operate at higher temperatures.

Most parts machined in the workshop are made from metal or plastic. In recent years, we have witnessed a growing demand for the use of new materials such as Peek. Peek is a fairly new material. It has become an increasingly popular material, replacing PTFE for sample holders, as it doesn’t contaminate the material which is being tested, is a more stable material from a machining perspective and is able to operate at higher temperatures.

Can you tell us more about collaborations and projects that you have been involved with?

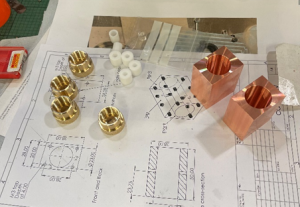

Mike: We have opportunities to be involved with unique research projects. For example, I enjoyed machining parts to support Professor Neil Alford with his research into diamond masers (a microwave laser) which work at room temperature. This idea was suggested in the 1970’s but no one had managed to create a diamond maser because they all used microwave cavities – a metallic cylinder with connectors – made by the manufacturer of the big magnets used in the experiment. Professor Alford asked if I could create a cavity in oxygen free copper to support the world’s first diamond maser. The group are now trying to miniaturise the device, so I’m helping to build microwave cavities for this research.

Russell: We’ve also machined parts to support the ‘design study’ projects created by our undergraduate students. Sometimes, they just needs a small part or tweak to get it working properly! Recently we have created hundreds of custom ‘materials bucky ball’ key rings for the Great Exhibition Road Festivals and Open Days too, which was a new challenge!

What do the team most enjoy about their roles in the workshop?

What do the team most enjoy about their roles in the workshop?

Russell: What I enjoy most about the role is meeting people and working with the team. In the workshop, you get to work with many people with great ideas for making the world a better place. If we can be just a small part of that stepping stone to support their research, it can feel very rewarding.

Mike: I’ve really enjoyed the opportunity to train our apprentices. I first started training apprentices 11 years ago, and I’m currently training my last! It’s been fantastic to see younger technicians learn new skills over the years and take these forward in their new roles.