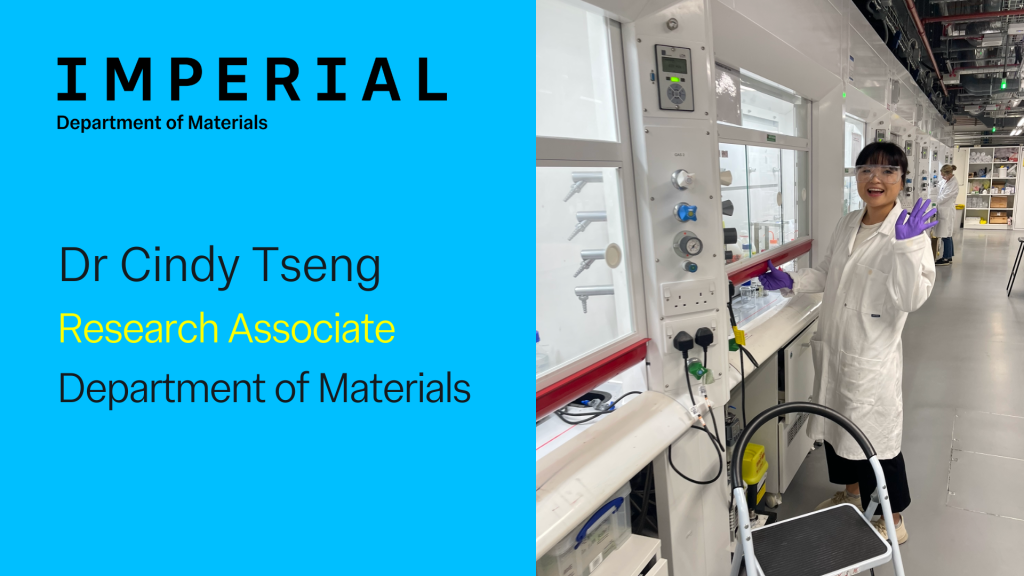

Dr Cindy Tseng is a Research Associate in the Department of Materials. Her research investigates new materials that could produce green hydrogen cheaply and more efficiently for renewable energy applications. In this new blog post, she shares more about her research, how it could make an impact and what she enjoys outside of research.

What inspired you to become a Materials Scientist?

I wanted to make a meaningful impact by working towards sustainable research. My PhD was very focused on fundamental studies, which helped me develop strong analytical and critical thinking skills. However, for my next academic chapter, I wanted to be more involved in renewable energy applications. A major challenge in this field is gaining a better understanding of catalyst materials so we can design alternatives that are easier to scale up.

How would you explain your research to someone outside the field?

I am investigating new materials that can produce green hydrogen cheaply and, ideally, more efficiently for renewable energy applications.

Why did you study this area, and why is it important?

Materials are crucial because many green hydrogen technologies depend on precious metals as active materials. Unfortunately, the limited availability and high cost of these metals pose significant challenges to scaling up these technologies to meet global energy demands. And therefore, there is a pressing need to develop methods to reduce the reliance on these precious metals. I chose to stay in this field not only because of its importance but also because you can study a lot of interesting and fun (shiny) materials like gold, platinum, and iridium.

How could this research make an impact?

Success in my research means discovering and designing new catalyst materials that can lead the way in producing green hydrogen, the future fuel for electricity and other energy needs. This progress will significantly advance our efforts to fight global warming and achieve net-zero emissions by around 2050.

Who do you collaborate with at Imperial and beyond?

My research is collaborative and involves a large team of many people. Some include but are not limited to, Lucas Garcia-Verga, Alice Meng, Guangmeimei Yang, Caiwu Liang, Reshma Rao, Daniele Benetti, and Hanzhi Ye. Beyond Imperial, I collaborate with the University of Manchester, the University of Cambridge, BP, Diamond Light Source, and Teer Coatings.

What do you enjoy most about what you do?

The people. Imperial is one of the leading universities equipped with cutting-edge instruments that allow me to push the boundaries of my research. But what I value most is working with my colleagues and bosses. You can find smart people at any good university, but here, I’m surrounded by incredibly helpful, understanding, and fun colleagues who have become some of my closest friends. They make going to work enjoyable and help brighten gloomy (figuratively and literally) days when things don’t work, which is all the time. At work, I feel safe to ask questions and learn. Besides having the tools to excel as a researcher, I’m also growing in essential soft skills like clear communication, empathy for others, and data organisation.

What do you enjoy outside of research?

I enjoy exploring new bakeries—I am on a mission to find the best carrot cake and Japanese cheesecake. To relieve stress, I enjoy taking high-intensity workout classes and watching horror movies (although that adds stress to most people!).

What’s something your colleagues would be surprised to learn about you?

I was cast for a Burger King Whoppers commercial in Los Angeles when I did my PhD there.

Batteries and other energy storage solutions are critically important right now because, while solar and wind power are becoming very economically viable, they only provide intermittent power, and batteries are needed to level out this supply. The current lithium battery technologies use very unsustainable materials and the best alternatives just don’t have the same performance or lifetime. If we can understand how they degrade, then we can find ways to improve them.

Batteries and other energy storage solutions are critically important right now because, while solar and wind power are becoming very economically viable, they only provide intermittent power, and batteries are needed to level out this supply. The current lithium battery technologies use very unsustainable materials and the best alternatives just don’t have the same performance or lifetime. If we can understand how they degrade, then we can find ways to improve them.

I have always been interested in the energy sector and completed research placements during my bachelor’s and master’s on organic batteries and solar cells. During the last year of my master’s, I became more interested in the materials science of the active layers in the devices than in the device fabrication, which had been my main interest until then. It fascinated me how you can shape the device, but it felt a bit like skipping a step not knowing well how the materials in it are oriented and interact. Deciding what the right use for a material depends on its structural and functional properties feels more natural to me and can lead us to targeted and informed device fabrication, so that is how I got into characterisation.

I have always been interested in the energy sector and completed research placements during my bachelor’s and master’s on organic batteries and solar cells. During the last year of my master’s, I became more interested in the materials science of the active layers in the devices than in the device fabrication, which had been my main interest until then. It fascinated me how you can shape the device, but it felt a bit like skipping a step not knowing well how the materials in it are oriented and interact. Deciding what the right use for a material depends on its structural and functional properties feels more natural to me and can lead us to targeted and informed device fabrication, so that is how I got into characterisation.

What did you learn?

What did you learn?

During the project, I learnt a lot about leadership in a large team and how

During the project, I learnt a lot about leadership in a large team and how

exploration and entertainment

exploration and entertainment

One of the top reasons I enjoy studying Material Science and Engineering at Imperial is the mix of coursework and exams within the degree program. I’m currently going strong in my second year (I hope!) and I have already completed over ten labs, where I’ve conducted interesting experiments like polymer synthesis and cooling curve measurement.

One of the top reasons I enjoy studying Material Science and Engineering at Imperial is the mix of coursework and exams within the degree program. I’m currently going strong in my second year (I hope!) and I have already completed over ten labs, where I’ve conducted interesting experiments like polymer synthesis and cooling curve measurement. It is always exciting when what you learn connects with the real world. During my summer internship at SKF Sweden, I saw and applied many skills from my first year. The sample preparation skills I learned came in handy when I cut, ground, and polished various bearing samples. My understanding of steel phase diagrams also allowed me to hold insightful conversations with the company’s heat treatment expert. Now in my second year, many things that I didn’t understand before are becoming clearer and clearer.

It is always exciting when what you learn connects with the real world. During my summer internship at SKF Sweden, I saw and applied many skills from my first year. The sample preparation skills I learned came in handy when I cut, ground, and polished various bearing samples. My understanding of steel phase diagrams also allowed me to hold insightful conversations with the company’s heat treatment expert. Now in my second year, many things that I didn’t understand before are becoming clearer and clearer.

I first became interested in Materials Science and Engineering because I wanted to understand what makes certain things more fragile than others or more susceptible to breaking and failure! This is only the smallest part of Materials Science and Engineering, as I would discover during my time at Imperial.

I first became interested in Materials Science and Engineering because I wanted to understand what makes certain things more fragile than others or more susceptible to breaking and failure! This is only the smallest part of Materials Science and Engineering, as I would discover during my time at Imperial.