Céline Bourquin, an undergraduate student in the Department of Materials, shares her experience interning at Safran Tech, the research and technology branch of Safran, where she worked in the experimental casting lab for advanced turbine blades.

Safran is a French aerospace company that designs and produces engines for aircraft, helicopters and rockets, and aeronautical and military equipment. My one-month internship took place in the laboratory for experimental casting of advanced turbine blades, on the Safran Aircraft Engines site.

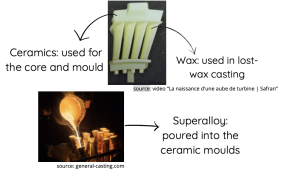

The lab team works on characterising materials such as metals, wax, ceramics or superalloys and analyse their interactions, with the objective to improve their properties under extreme conditions such as high temperatures and high stress. While some of their projects focus on finding the microstructures necessary for ideal mechanical properties, others concentrate on elaborating programmes such as heat treatment methods.

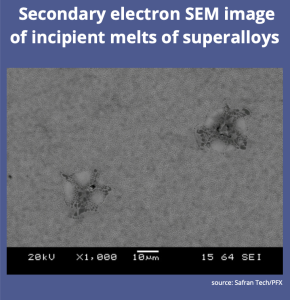

During this internship, I contributed to the sample preparations for the analysis of heat-treated superalloys. Heat treatment is a process that involves heating and cooling materials to achieve desired properties. The process begins by heating the material to a specific temperature, which allows for changes in its microstructure. After reaching the desired temperature, the material is cooled at a controlled rate. In my work, I observed the samples under the microscope to check at which temperatures incipient melts start to appear after cutting, mounting and polishing. The incipient melts indicate chemical segregation, or non-homogeneous composition, which would lead to a decrease in desired mechanical properties and ultimately to reduced engine efficiency. These analyses are necessary to identify which heat-treatment programmes are more adapted to the alloy, and what changes are needed to improve the programmes.

This was my first industrial work experience. I was positively surprised and relieved to discover that what we had learnt in the first year courses was used and referred to regularly in this laboratory. I felt reassured that I wasn’t completely out of place, and that I could perhaps contribute at least a little to their projects. The internship also gave me the opportunity to learn more about large corporations, their processes and culture. In particular, due to the nature of the work carried out in the lab, there was great emphasis placed on safety and security. I was very grateful to the team who made me feel welcome and useful. Everyone was very positive which made going to work enjoyable and I learnt that team dynamics really influence workplace ambiance. Nonetheless, I must admit I was exhausted at the end of each day, but it was a kind of tiredness that comes from doing something new and rewarding. Looking back, I finished each day feeling a little more confident and excited about the path I’d chosen.