Some while ago in 2010 I commented on the many problems facing people like me when trying to playback video archive material. The problem is that tape manufacturers never realised, in the mid 1970’s, that they had created formulations for magnetic tape that were going to cause problems in about 20 years time. Almost all of the video and some audio tapes held at Imperial are now suffering from what is called Sticky Shed Syndrome. It’s a great name for the Goo that comes off of the tapes when you try to play them. A report into this problem said “Somewhere between 20% and 80% of all U-Matic (video) tapes are showing obvious signs of decay or are giving the archives holding them cause for concern. U-Matic is widely considered by the major broadcast archives in Europe as the top priority format for video preservation. U-Matic transfers take between 1-2 hours of operator time per hour of programme material for tapes in good condition, rising to 5-10 hours per hour or more for difficult media.”

Some while ago in 2010 I commented on the many problems facing people like me when trying to playback video archive material. The problem is that tape manufacturers never realised, in the mid 1970’s, that they had created formulations for magnetic tape that were going to cause problems in about 20 years time. Almost all of the video and some audio tapes held at Imperial are now suffering from what is called Sticky Shed Syndrome. It’s a great name for the Goo that comes off of the tapes when you try to play them. A report into this problem said “Somewhere between 20% and 80% of all U-Matic (video) tapes are showing obvious signs of decay or are giving the archives holding them cause for concern. U-Matic is widely considered by the major broadcast archives in Europe as the top priority format for video preservation. U-Matic transfers take between 1-2 hours of operator time per hour of programme material for tapes in good condition, rising to 5-10 hours per hour or more for difficult media.”

All of this is what I’m now experiencing with batches of U-Matic videotapes that I’m trying to get onto DVD and then after that, onto the Imperial YouTube channel. What happens, when you play a tape, is that you will very rapidly start to hear the typical screeching noise of the tape sticking to interior parts of the recorder and you’ll soon be taking the cover off of the recorder, as seen on the right. At this point the tape will almost certainly have come to a complete halt all on its own. The ‘binder’, which holds both the magnetic oxide and the back-coating onto the plastic, is slowly breaking down. It’s absorbed moisture over a period of time and has gone slightly sticky. This is primarily because the tapes were never stored in air conditioned locations. Ampex is one of the companies that had the problem with sticky tapes (most of our tapes are from Ampex). In 1993, they created a patent for overcoming these playback problems by heat-treating tapes and I have now resorted to this approach. For those engineers reading this, here’s the extract from what they patented: “…Polymers can react with water from atmospheric moisture to break the ester linkages contained in such polymeric chains and form lower molecular weight polymers, a process known as hydrolysis. When a sufficient number of such bonds have been hydrolyzed and broken, the binder becomes undesirably weakened due to degeneration of molecular weight. The breakdown compounds of this weakened binder migrate, can exude from the coating thus causing the tape to be sticky and to shed.“

All of this is what I’m now experiencing with batches of U-Matic videotapes that I’m trying to get onto DVD and then after that, onto the Imperial YouTube channel. What happens, when you play a tape, is that you will very rapidly start to hear the typical screeching noise of the tape sticking to interior parts of the recorder and you’ll soon be taking the cover off of the recorder, as seen on the right. At this point the tape will almost certainly have come to a complete halt all on its own. The ‘binder’, which holds both the magnetic oxide and the back-coating onto the plastic, is slowly breaking down. It’s absorbed moisture over a period of time and has gone slightly sticky. This is primarily because the tapes were never stored in air conditioned locations. Ampex is one of the companies that had the problem with sticky tapes (most of our tapes are from Ampex). In 1993, they created a patent for overcoming these playback problems by heat-treating tapes and I have now resorted to this approach. For those engineers reading this, here’s the extract from what they patented: “…Polymers can react with water from atmospheric moisture to break the ester linkages contained in such polymeric chains and form lower molecular weight polymers, a process known as hydrolysis. When a sufficient number of such bonds have been hydrolyzed and broken, the binder becomes undesirably weakened due to degeneration of molecular weight. The breakdown compounds of this weakened binder migrate, can exude from the coating thus causing the tape to be sticky and to shed.“

Heat treating or Baking as it’s called, is now considered (and used throughout the World) as a method for overcoming playback problems when most other things have been tried and failed. So, this week I attempted this approach myself. You need a way of continuously heating the tapes to between 50-54oC and for several hours. Not wanting a lab oven here at home (where I’m slowly transferring the archive) I resorted to the other suggested method of using a digital controlled food dehydrator. Ebay to the rescue and installation complete (pic above) my first attempt was carefully monitored with an external temperature probe

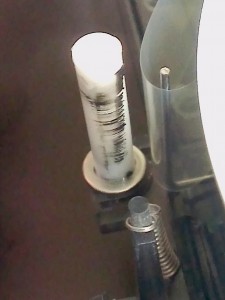

Heat treating or Baking as it’s called, is now considered (and used throughout the World) as a method for overcoming playback problems when most other things have been tried and failed. So, this week I attempted this approach myself. You need a way of continuously heating the tapes to between 50-54oC and for several hours. Not wanting a lab oven here at home (where I’m slowly transferring the archive) I resorted to the other suggested method of using a digital controlled food dehydrator. Ebay to the rescue and installation complete (pic above) my first attempt was carefully monitored with an external temperature probe  during the few hours that I heated the tapes for. I had partial success when running the first tape, but it needed a bit more treatment. I also discovered that the inside of the actual tape cassette has small plastic guides which were also getting goo on them. This was causing more problems than inside the actual tape machine. So, take the tapes apart (pic on right), clean the guides, heat them again, let them cool down and reassemble. Success with the first tape! It played back all the way through and was now onto DVD. The next tape was still causing problems and I soon discovered the typical screeching noise was now coming from inside the cassette rather than the playback machine.

during the few hours that I heated the tapes for. I had partial success when running the first tape, but it needed a bit more treatment. I also discovered that the inside of the actual tape cassette has small plastic guides which were also getting goo on them. This was causing more problems than inside the actual tape machine. So, take the tapes apart (pic on right), clean the guides, heat them again, let them cool down and reassemble. Success with the first tape! It played back all the way through and was now onto DVD. The next tape was still causing problems and I soon discovered the typical screeching noise was now coming from inside the cassette rather than the playback machine.  Looking at the cassette I could see that the interior plastic guides were once again coated with goo (pic on left). I put my finger on the guide and it stuck there like sticky tape! So, after taking the cassette apart for the third time and cleaning the guides it played OK. Interestingly I’ve not found any references to these guides inside the cassettes being part of the problem, it’s only references to inside the tape machine. Anyway, the last tape is now onto DVD. A saga indeed and very time consuming (two days for two tapes), but a great feeling of success when I beat the Goo. Baking is THE way it seems. All I have to do is now work my way through the other few hundred video tapes. Incidentally, these current tapes are all from our Maths series made with the London Mathematical Society (LMS) and are now on the YouTube channel in the LMS Playlist. The picture below is of the first successful replay after heat treatment of tape number one. It needed a touch of tender care with TBC adjustments for brightness, colour, sharpness and so on, but looks pretty good after 27 years of being on a cupboard shelf.

Looking at the cassette I could see that the interior plastic guides were once again coated with goo (pic on left). I put my finger on the guide and it stuck there like sticky tape! So, after taking the cassette apart for the third time and cleaning the guides it played OK. Interestingly I’ve not found any references to these guides inside the cassettes being part of the problem, it’s only references to inside the tape machine. Anyway, the last tape is now onto DVD. A saga indeed and very time consuming (two days for two tapes), but a great feeling of success when I beat the Goo. Baking is THE way it seems. All I have to do is now work my way through the other few hundred video tapes. Incidentally, these current tapes are all from our Maths series made with the London Mathematical Society (LMS) and are now on the YouTube channel in the LMS Playlist. The picture below is of the first successful replay after heat treatment of tape number one. It needed a touch of tender care with TBC adjustments for brightness, colour, sharpness and so on, but looks pretty good after 27 years of being on a cupboard shelf.

Colin Grimshaw April 2014

Fascinating. I wonder how many hours are being spent across the world dealing with these problems. I also wonder how many valuable tapes will eventually become unreadable beyond all hope. I hope all the video archivists out there know about this.

Indeed yes Steve. I doubt many actually appreciate how their archive will suddenly become unplayable and potentially lost for ever. Not only is there this particular problem, but that of access to working U-Matic machines, now classified as ‘rare’ in the industry…but that’s another story!

Hi Colin, above all congratulations for your interesting article. I’ve got a question for you. I’m using a Sony VO-9600P VCR Deck with Kramer SP-11D TBC in order to digitalize a fifties late 70s early 80s U-matic tapes. I’ve noticed that TBC unit sometimes adds a horizontal green line in correspondence with low bottom glitches. Did this happen to you too? Thanks in advance for your kind attention. Regards